窒化アルミニウム加熱セラミックプレートは、以下を使用して作られた加熱要素またはヒーターキャリアです。 窒化アルミニウムセラミックス 基質またはコアコンポーネントとして。

材料

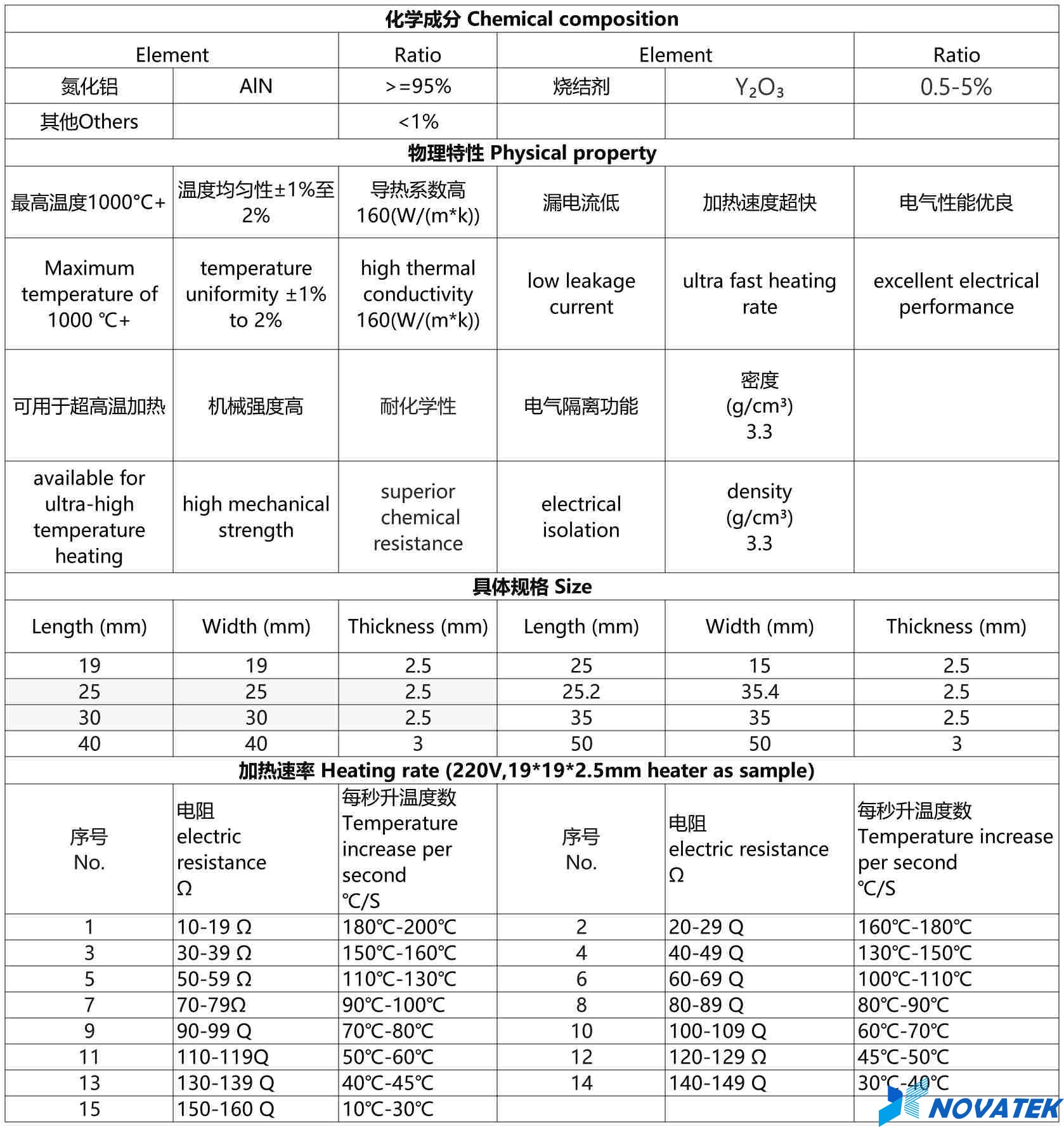

Al2O3 / AlN密度

3.30~3.70 g/cm3色

白 / グレー▼主な利点:

超高熱伝導率: AlNセラミックは、アルミナセラミックをはるかに凌駕する優れた熱伝導率(理論値:約320W/mK、実用値:170~220W/mK)を誇ります。これにより、発熱体(抵抗回路など)からターゲット表面への迅速かつ均一な熱伝達が可能になり、熱応力を最小限に抑えながら効率と温度均一性を向上させます。

優れた電気絶縁性: 高い絶縁強度と抵抗率により、特に高電圧または電気的に絶縁されたアプリケーションで安全性が確保されます。

低熱膨張係数: シリコン チップ (半導体) に適合し、半導体デバイス (IGBT、レーザーなど) の加熱/温度制御時に信頼性の高い熱適合性を提供します。

高い機械的強度と硬度: 堅牢な構造サポートと耐久性を実現します。

耐高温性と耐腐食性: 高温(長期間 800°C 以上)および過酷な化学環境でも安定したパフォーマンスを発揮します。

低誘電率/損失: 高周波アプリケーションに最適です。

▼主な用途:

半導体製造およびテスト: ウェーハチャック、プローブステーションホットプレート、パッケージテスト。

高出力エレクトロニクスの熱管理: IGBT モジュール、レーザー ダイオード (LD)、高出力 LED (多くの場合、薄膜/厚膜加熱回路が統合されています) 用の熱拡散基板。

精密機器: 高速で均一かつ安定した加熱を必要とする機器(例:分析機器、真空部品)。

高温センサーパッケージベース。